ABOUT US

About KUROIWA

ABOUT US

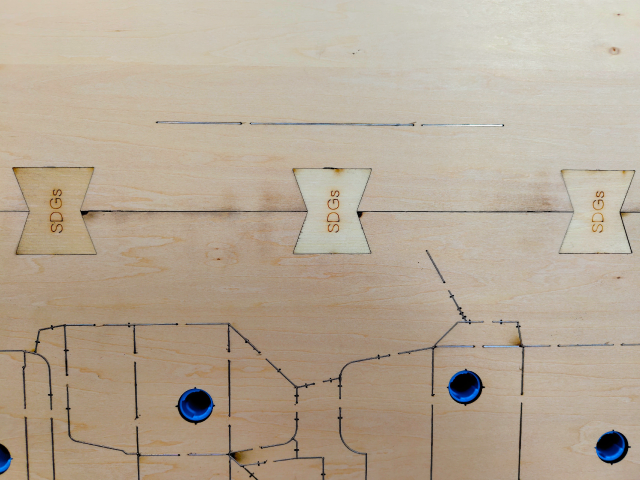

The philosophy embodied in “Yajirobe”

Kuroiwa’s logo is derived from the “Yajirobe” traditional balance toy,

symbolizing our belief that “balance is everything” in die creation.

True value arises not from merely selecting high-performance parts,

but from each element functioning in optimal balance.

The philosophy embodied in “Yajirobe”

Kuroiwa’s logo is derived from the “Yajirobe” traditional balance toy,

symbolizing our belief that “balance is everything” in die creation.

True value arises not from merely selecting high-performance parts,

but from each element functioning in optimal balance.

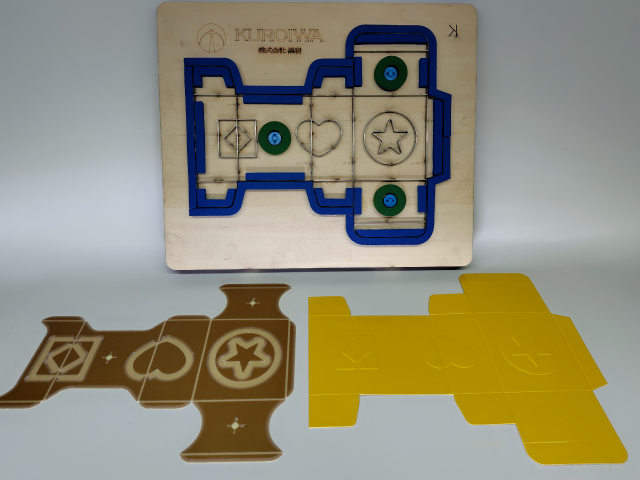

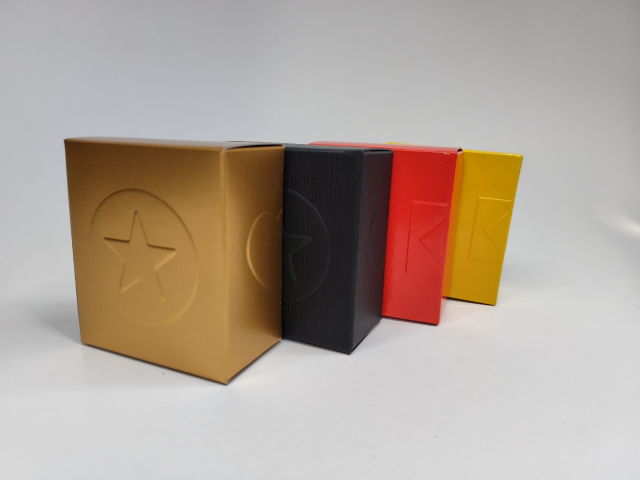

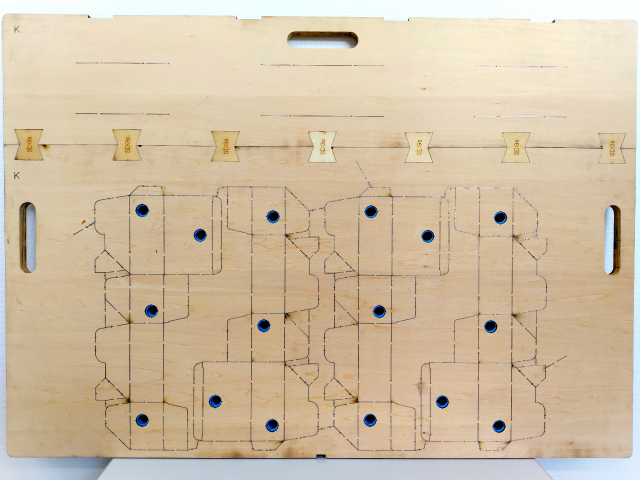

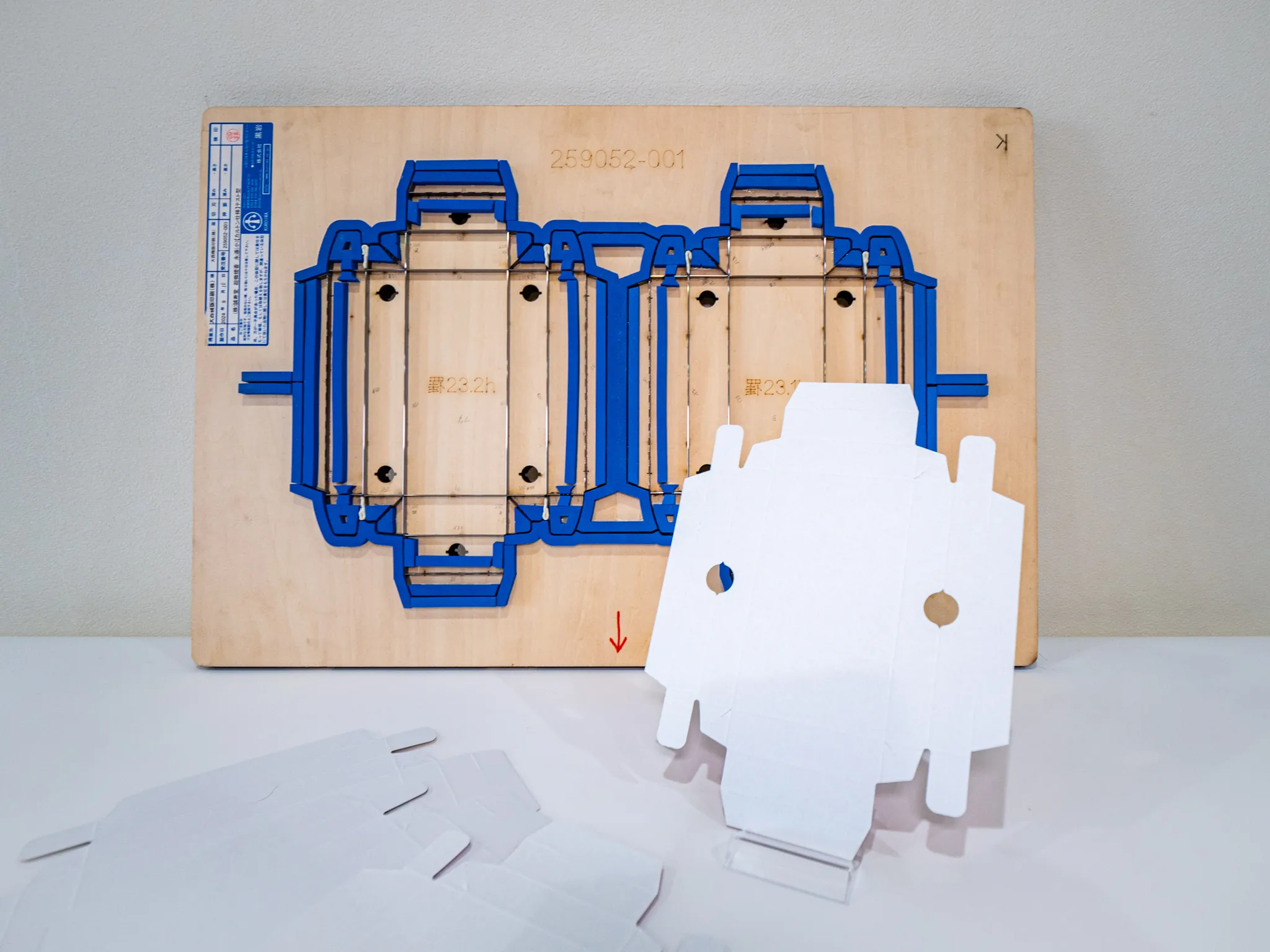

One - Stop

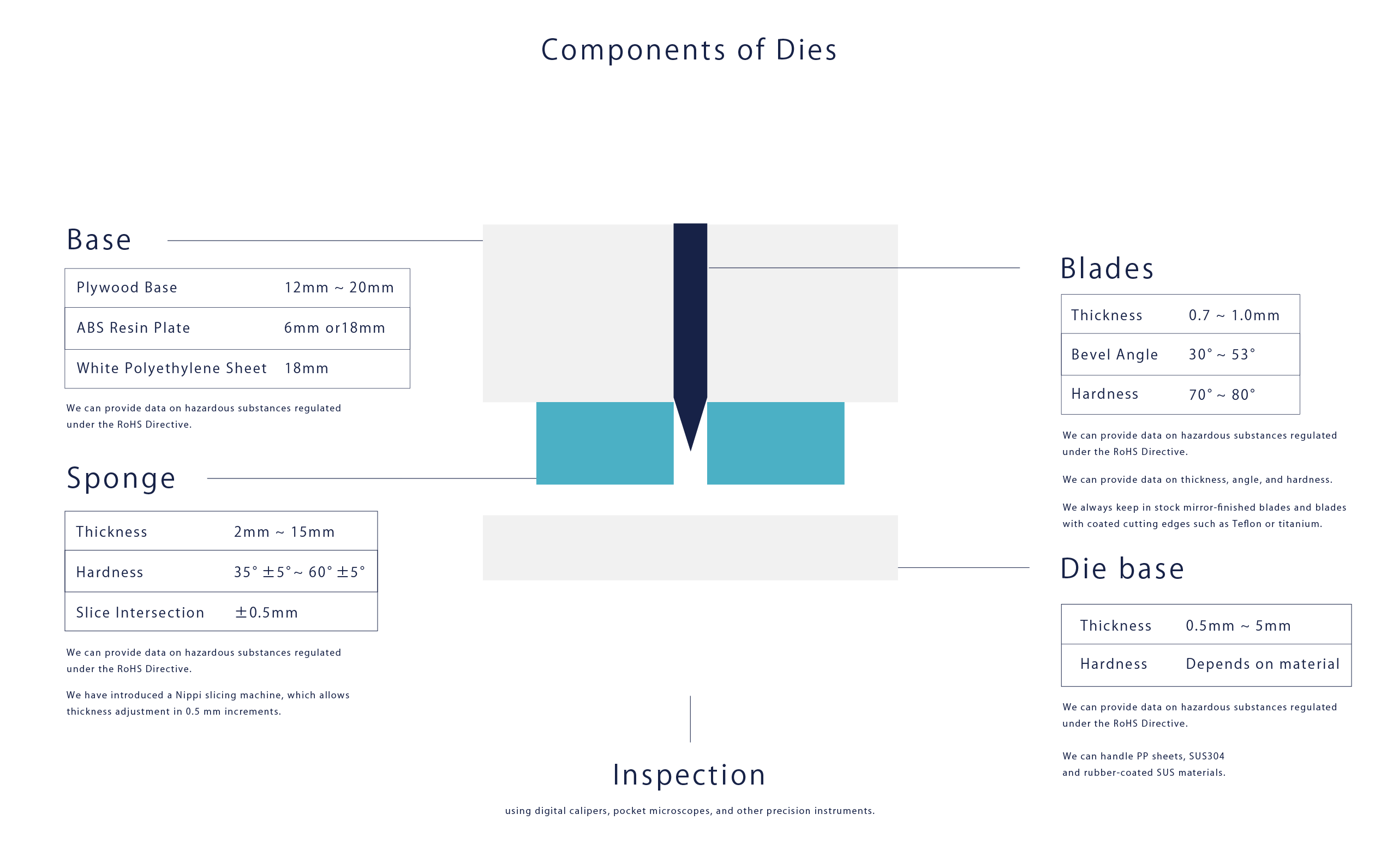

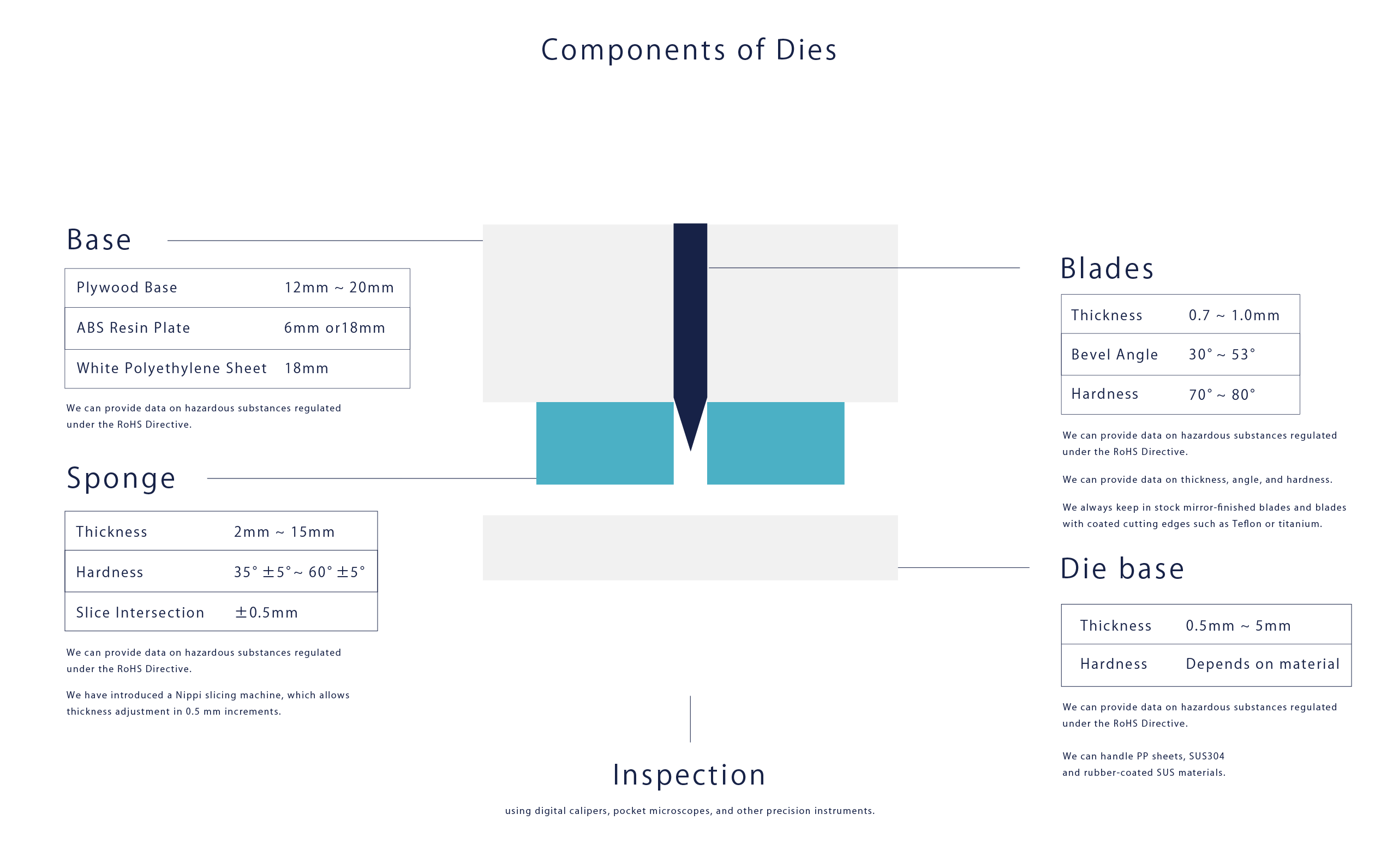

The combinations are endless.

There is a vast array of choices in die cutting.

We propose custom dies optimized for material

and processing needs, balancing the entire structure for each customer.

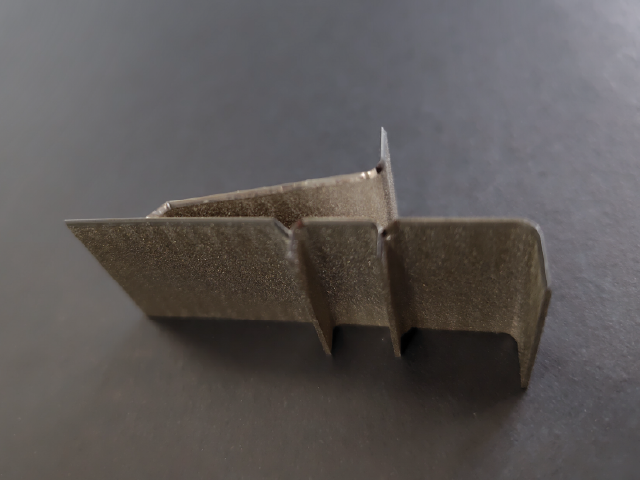

High - Quality

Kuroiwa’s Strength

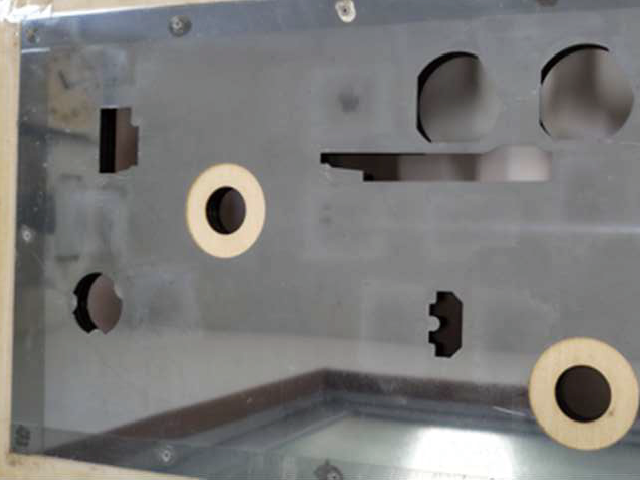

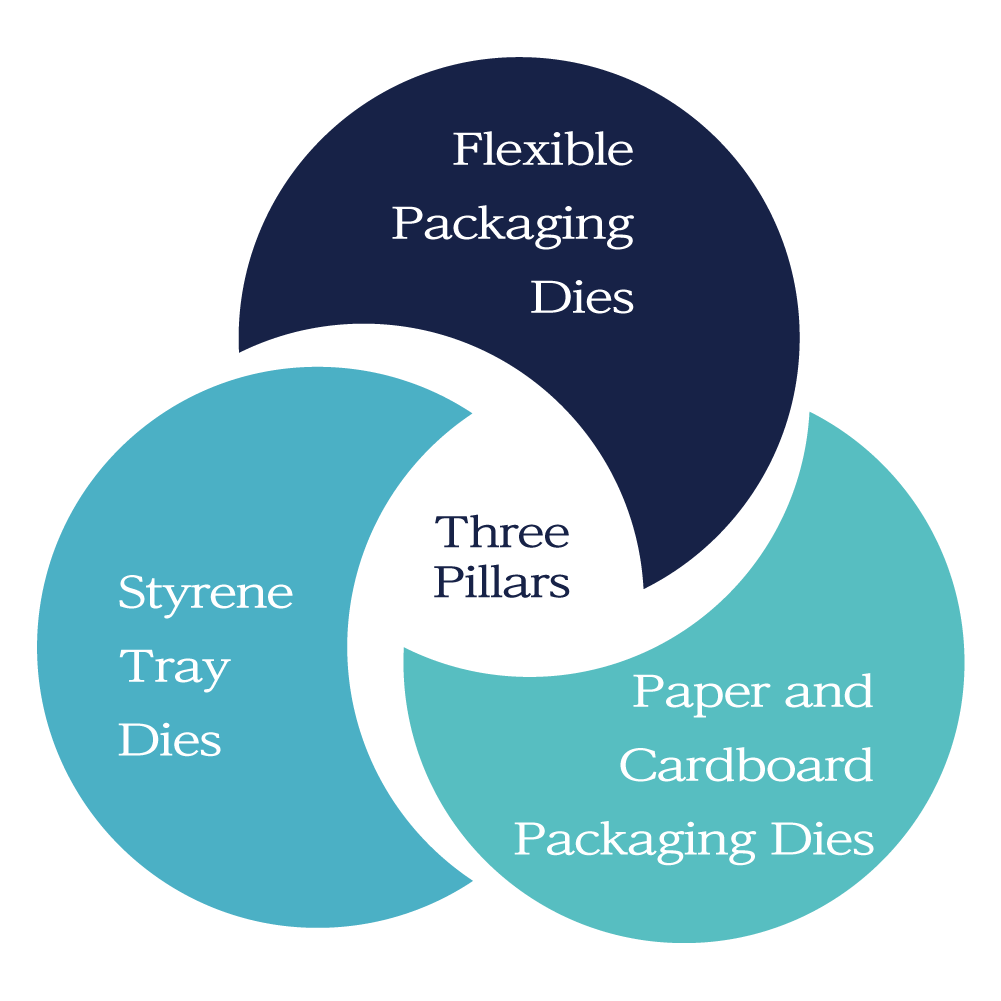

Kuroiwa’s strength lies in its “three pillars.”

Though they may appear distinct fields, the technologies can be widely applied across them.

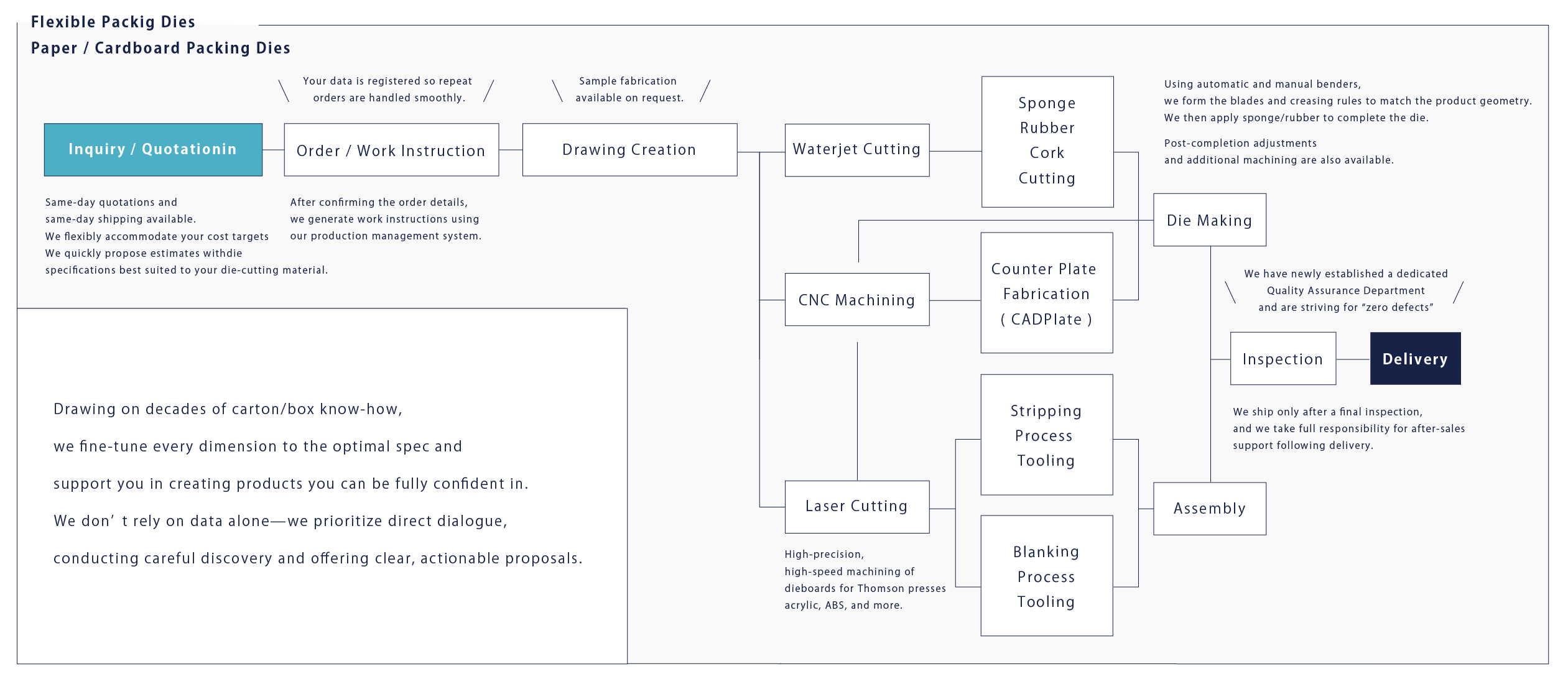

Flexible Packaging Dies

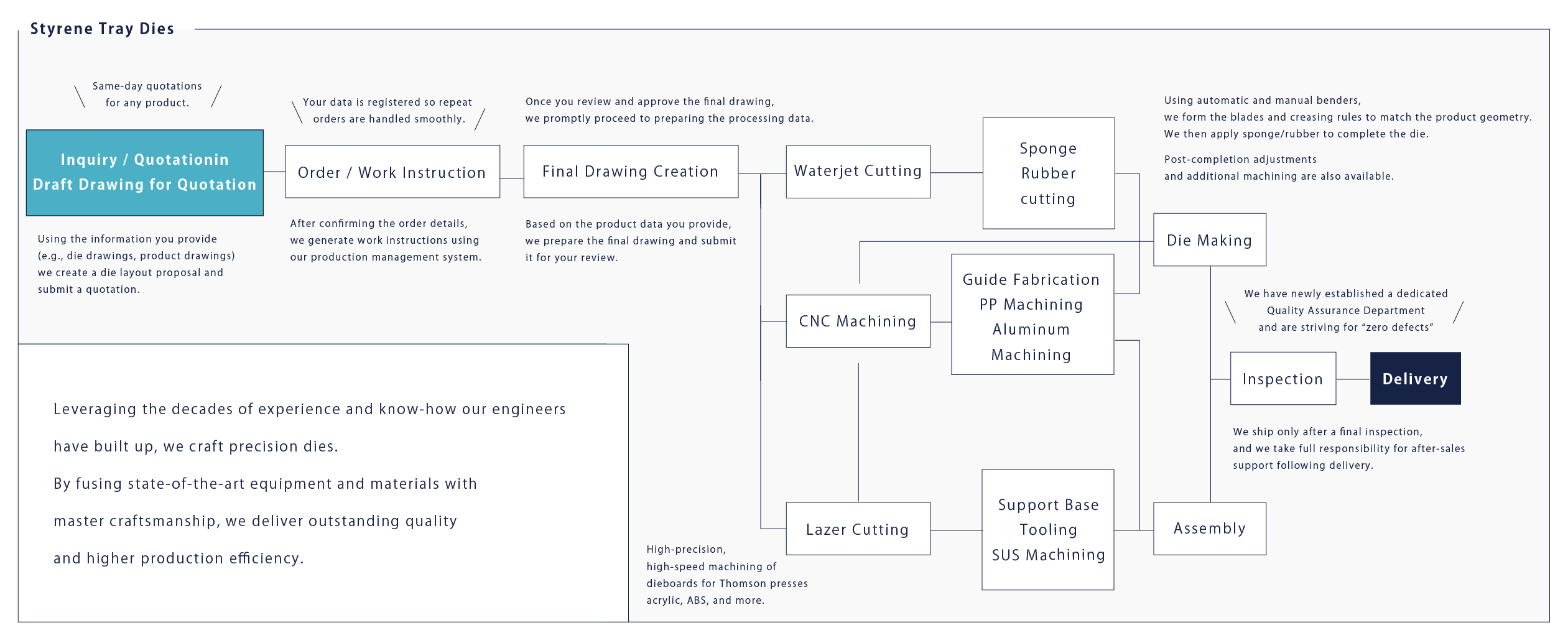

Styrene Tray Dies

Paper and Cardboard Packaging Dies

These pillars resonate together,

forming one strong foundation that drives technical strength, quality, and efficiency.

This has become the basis of Kuroiwa’s unique position in the industry.