SERVICES

Our Services

SERVICES

Kuroiwa's Craftsmanship and Commitment

We never skip the final finishing touch.

We always keep the end user in mind and strive to make every die even better.

Sixty years of refining every detail have built the technology and know-how that make Kuroiwa shine.

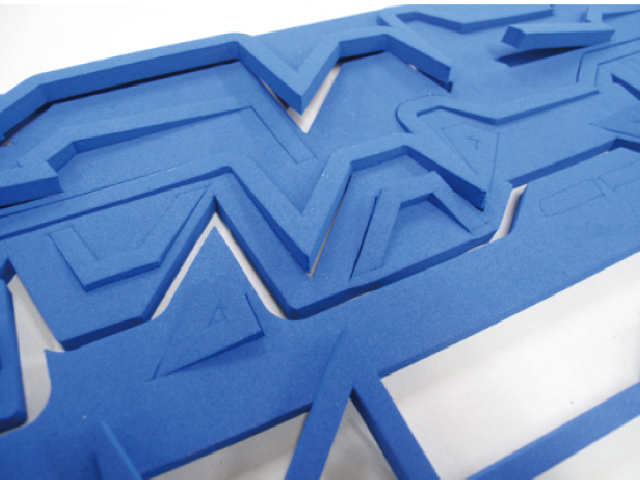

Flexible Packaging

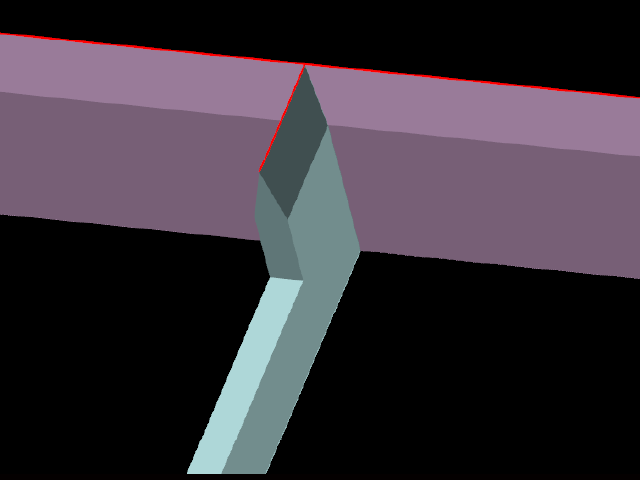

I-Notch

A straight profile formed with a 2 mm blade.

Our proprietary techniques secure short blades vertically in the plywood base,

which keeps them perfectly upright,

reducing deflection during processing.

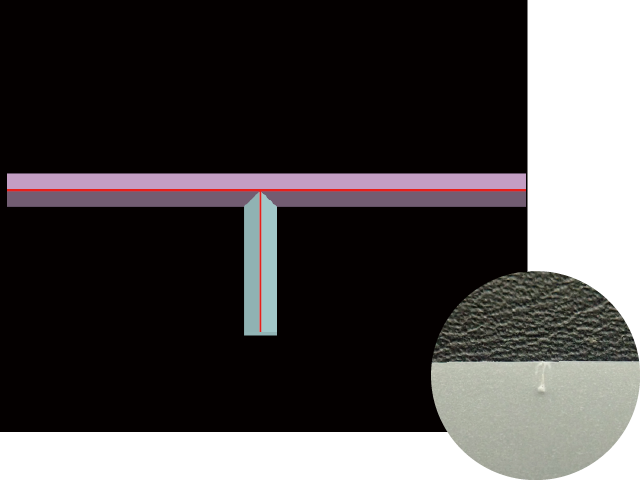

V-Notch

Formed by joining blades at acute angles.

To finish without gaps, the blade base is

hand-carved by skilled craftsmen.

It produces a sharp tear edge that opens easily,

but the joints can open at the tips, so durability is lower.

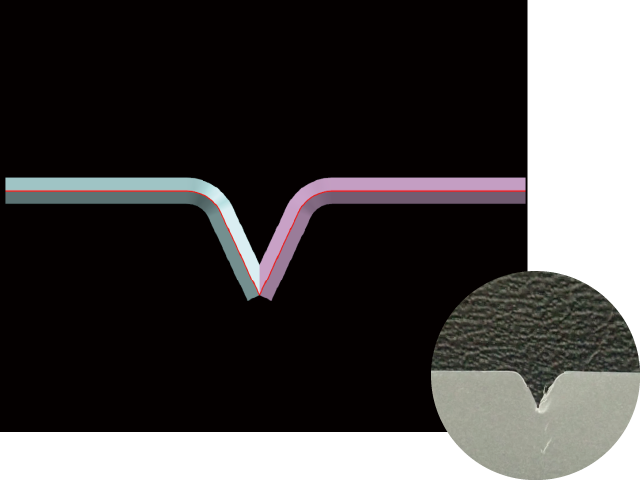

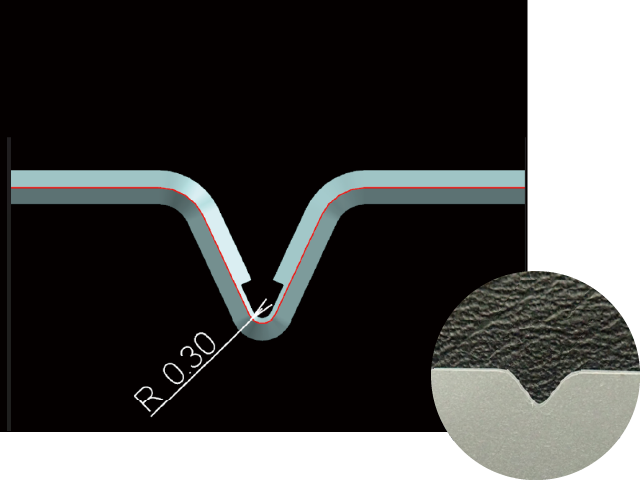

Broaching

Adds a radius to the tip of a V-notch profile.

By carving the base beneath the curved blade edge,

we can achieve smaller radii than usual.

With no joints, durability is high,

but the rounded tip makes tearing harder than a V-notch.

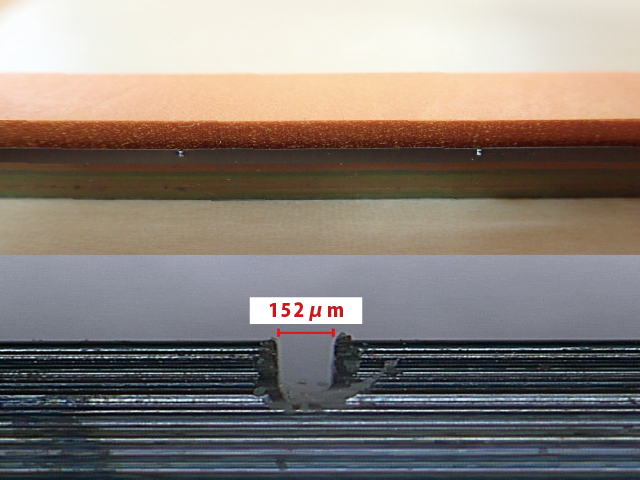

Joint Machining

Essential machining applied to the blade when processing sheets.

We machine precise joints on the cutting rules.

We support depths from 0.9 mm and widths from 0.15 mm,

enabling fine adjustments.

Trays

Rubber + SUS

Laminates rubber and stainless steel together

for use on the pressure side of integrated blades.

The rubber cushions and absorbs cutting pressure,

improving blade durability and shortening leveling time.

Floating

Designed for multi-up styrene forming.

Blades move with sheet expansion and contraction, automatically adjusting the punching position.

Angled Sponge Cut

Cutting the sponge into a trapezoid

helps it hold the sheet evenly when pressed,

maintaining stable positioning.

It prevents the sponge from covering the blade and helps avoid contamination.

Guide

Machined to match the product shape,

used to position and secure the sheet.

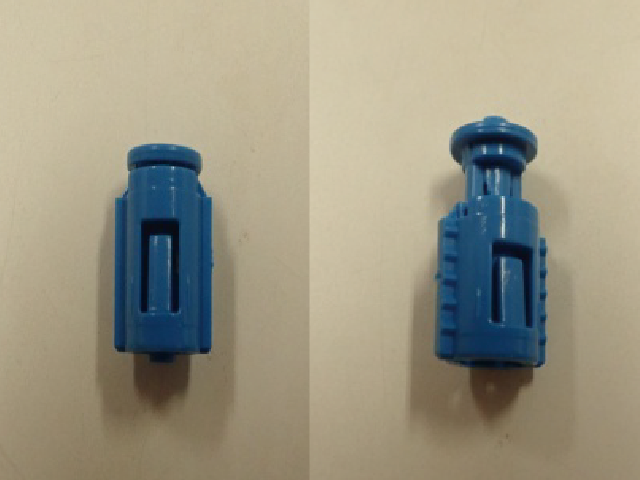

Turnbuckle

For multi-up styrene molding sheets,

the bolt-tightening mechanism

lets operators manually adjust the punching position,

allowing blade length to be tuned by up to 1.5 mm per location.

Paperboard / Cardboard

Stripping Die

Removes unwanted waste during the stripping process.

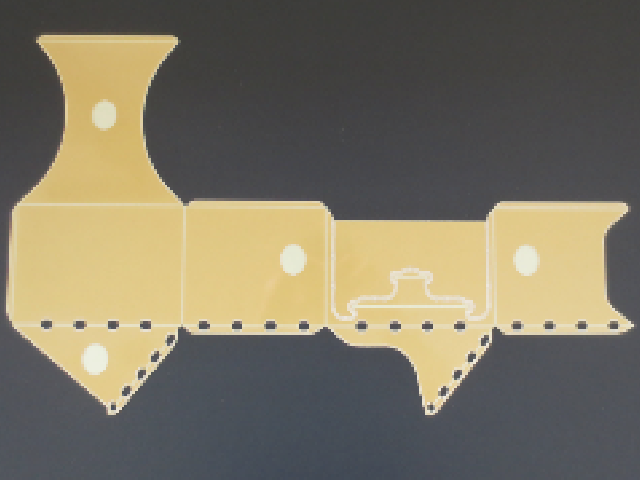

Blanking Die

Leaves scrap inside the machine while ejecting only the finished product.

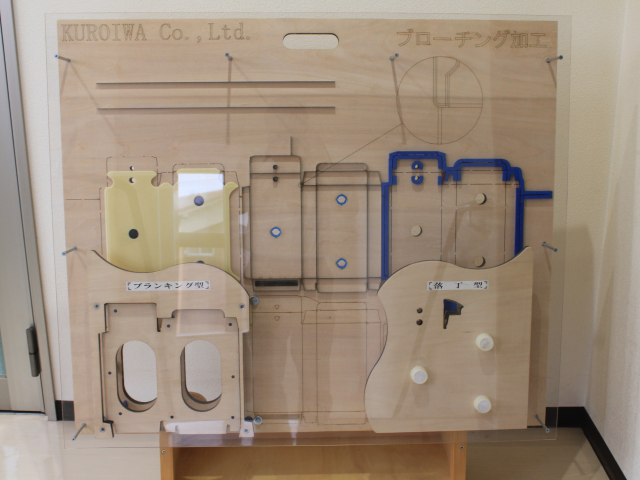

Broaching

Minimizes the bending radius of the blade

to prevent chipping at the joint.

King Pin

A jig used to set the CAD plate.

Delivered embedded in the die, so pulling the pin makes it easy to transfer the CAD plate

onto the stainless backup plate in one step.

Offers a relatively low initial cost.

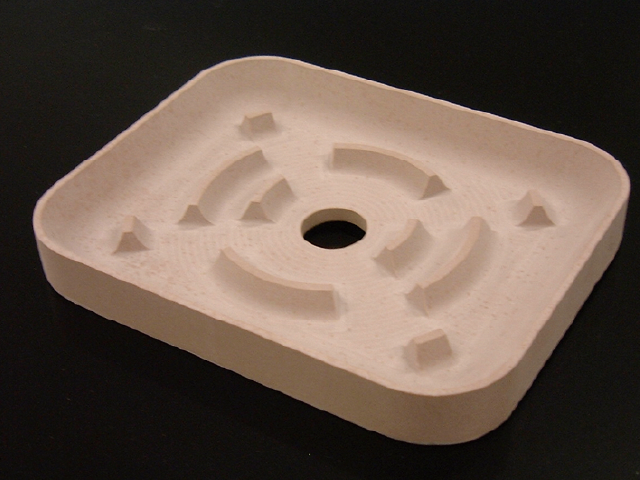

CAD Plate

Based on CAD data for Thomson dies, we create plate data and machine resin components with grooves along the crease lines.

Using jigs embedded in the wood die enables single-surface lamination without misalignment.

Compared with using creasing tape, setup time is reduced and fine crease patterns are supported.

Other Processing Equipment

Plywood Laser

Laser cutting machine: Shibuya Kogyo SPL (2312D)

Laser cutting machine: Shibuya Kogyo SPL (SPL3821D)

Max work size: 2100 × 1320

Primarily processes 9T to 20T plywood.

Also handles acrylic, resin, and other materials.

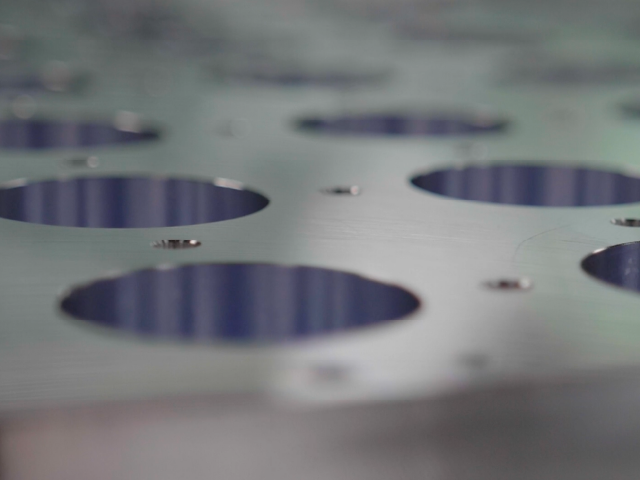

Metal Plate Laser

Laser cutting machine: Mitsubishi ML2512HVII-20CF3

Max work size: 2440 × 1220

Primarily processes SUS from 1T to 6T.

For carbon steel, we have results up to 16T.

Water Jet

Water jet cutting machine: Flow Japan MACH300

Max work size: 2000 × 1500

Processes Sanperca up to 60T.

Processes SUS up to 30T.

Machining

Gantry milling machine: Yamazaki Giken YZ1321

Max work size: 2000 × 1120

Aluminum machining up to 50T.

General-Purpose Automatic NC Router

Heian Corporation REX-IIB

Max work size: 1300 × 1300

Primarily processes PP 3T and 5T, and can also machine MC nylon

POM, and other materials.

Chemical wood machining up to 75T.

Other

Nick Tool

Used with flatbed dies / proven on bag-making lines

A pistol-style nick tool designed for Thomson blades.

Hold it vertically and pull the trigger to cut at a consistent width and depth using spring force.

Lightweight and easy for any operator to handle.

Available with tip sizes from 0.2 mm to 0.3 mm.

Japanese Patent No. 7792141

Equipment List

| Machine | Manufacturer | Model | Units |

|---|---|---|---|

| Laser cutting machine | Shibuya Kogyo | SPL2321D | 1 |

| Laser cutting machine | Mitsubishi | ML2512HVII-20CF3 | 1 |

| Laser cutting machine | Shibuya Kogyo | SPL (SPL3821D) | 1 |

| Water jet cutting machine | Flow Japan | MACH300 | 1 |

| Gantry milling machine | Yamazaki Giken | YZ1321 | 1 |

| YAG laser | Miyachi Technos | ML-2450A | 1 |

| General-purpose automatic NC router | Heian Corporation | REX-IIB | 1 |

| Automatic rule bending machine | SUNTEX | - | 6 |

| Automatic high rule bending machine | SUNTEX | - | 2 |

| Sample cutting machine | NSK | Kongsberg XL20 | 1 |

| Sample cutting machine | ACS | AS1212FW | 1 |

| Automatic counter plate machine | NSK | CREAS LINE 8ATC | 1 |

| Hydraulic press | Toko | SHDC 1300×1200-100T | 1 |

| Hydraulic clicker press | Toko | TCM-550A | 1 |

| Slicer | Nippi Machinery | MP-B650 | 1 |

| Handheld 3D measurement system | Keyence | XM-5000 | 1 |

| Microscope | Keyence | VHX-6000 | 1 |

CONTACT US

Head Office

TEL: +8179-266-3628

FAX: 079-266-6810

3-28-33 Aoyamakita Himeji Hyogo JPN

Yumesaki Branch

TEL: +8179-280-3701

FAX: 079-280-3702

1082 Kochinosho Yumesakicho Himeji Hyogo JPN